In the modern industrial landscape, machine tooth technology plays an indispensable role in various manufacturing processes. Whether you're in the automotive, aerospace, or general machinery industry, understanding the intricacies of machine tooth is crucial for optimizing performance and achieving precision. Machine tooth refers to the teeth or cutting edges found on tools like gears, milling cutters, and other machinery used in material processing. These components are vital for efficient material removal and shaping.

As industries continue to evolve, the demand for advanced machine tooth technology has surged. Manufacturers worldwide are investing heavily in research and development to enhance the efficiency, durability, and precision of machine tooth tools. The evolution of machine tooth technology has brought about significant improvements in productivity and cost-effectiveness across multiple sectors.

This article aims to provide a detailed overview of machine tooth technology, covering its applications, benefits, maintenance, and future trends. Whether you're an engineer, technician, or simply someone interested in the mechanics behind modern machinery, this guide will equip you with the knowledge necessary to make informed decisions about machine tooth solutions.

Read also:Pro Wrestlers From Nc A Comprehensive Guide To North Carolinas Wrestling Stars

Table of Contents

- Introduction to Machine Tooth

- Biography of Machine Tooth Technology

- Types of Machine Tooth

- Applications of Machine Tooth

- Benefits of Machine Tooth Technology

- Maintenance and Care for Machine Tooth

- Materials Used in Machine Tooth Production

- Innovations in Machine Tooth Technology

- Challenges in Machine Tooth Usage

- Future Trends in Machine Tooth

- Conclusion

Introduction to Machine Tooth

Machine tooth represents a critical component in various industrial machinery, particularly in cutting tools and gear systems. The function of machine tooth is to facilitate the precise cutting or shaping of materials, ensuring accuracy and efficiency in manufacturing processes. These components come in a variety of designs, each tailored to specific applications, from heavy-duty industrial equipment to precision instruments.

Importance of Machine Tooth in Modern Industries

In today's manufacturing landscape, machine tooth is indispensable. It contributes significantly to the efficiency and accuracy of operations across multiple sectors. The technology behind machine tooth has advanced dramatically, allowing for the development of tools that can handle complex tasks with minimal error. This evolution has led to improved productivity and reduced operational costs for businesses worldwide.

Biography of Machine Tooth Technology

The history of machine tooth technology dates back to the early days of mechanical engineering. Over the years, advancements in materials science and manufacturing techniques have transformed the capabilities of machine tooth. Below is a brief overview of the development of machine tooth technology:

| Year | Milestone | Significance |

|---|---|---|

| 1800s | Introduction of basic gear systems | Laid the foundation for modern machine tooth technology |

| 1950s | Development of carbide cutting tools | Improved durability and efficiency of machine tooth |

| 1980s | Introduction of CNC machining | Enabled precise and automated production of machine tooth |

| 2000s | Advancements in coatings and materials | Increased lifespan and performance of machine tooth |

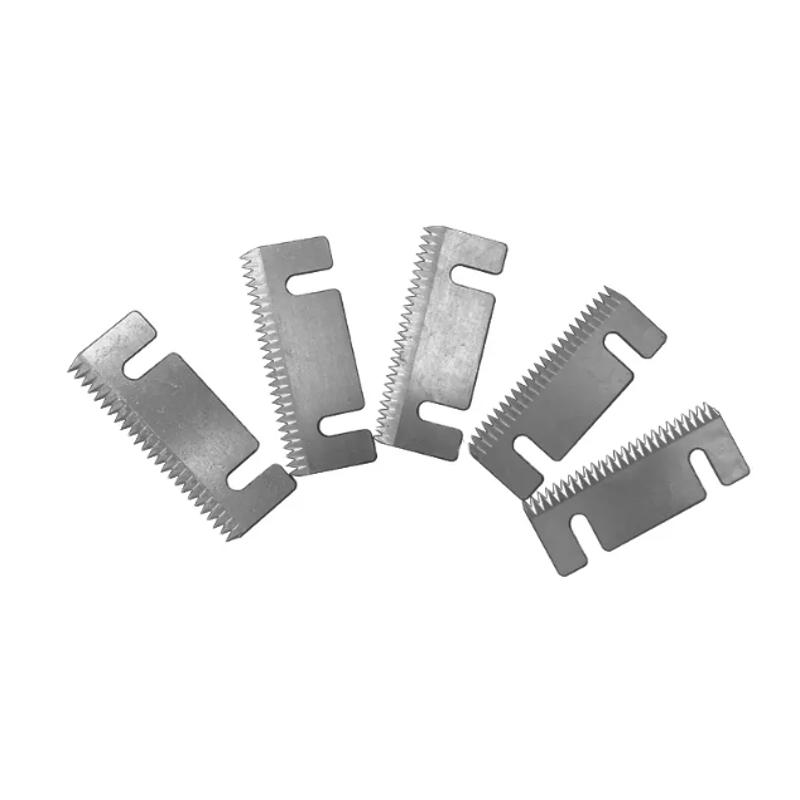

Types of Machine Tooth

Machine tooth comes in various forms, each designed for specific applications. Understanding the different types of machine tooth is essential for selecting the right tool for your needs.

Common Types of Machine Tooth

- Gear Teeth: Used in gear systems for power transmission

- Milling Cutters: Employed in milling machines for material removal

- Lathe Tools: Utilized in lathes for shaping and cutting materials

- Drill Bits: Designed for creating holes in various materials

Applications of Machine Tooth

Machine tooth technology finds application in a wide range of industries, including automotive, aerospace, construction, and manufacturing. Each industry leverages machine tooth for different purposes, such as cutting, shaping, and assembling components.

Key Applications Across Industries

For instance, in the automotive industry, machine tooth is used in gearboxes to ensure smooth power transmission. In aerospace, precision machine tooth tools are essential for crafting components that meet stringent safety standards. The construction sector utilizes machine tooth for cutting and shaping building materials, while the manufacturing industry relies on it for mass production of goods.

Read also:Lead Singer Of Cheap Trick A Comprehensive Look Into Robin Zanders Career And Legacy

Benefits of Machine Tooth Technology

Investing in machine tooth technology offers numerous advantages, including enhanced precision, increased efficiency, and reduced downtime. These benefits translate into cost savings and improved product quality for businesses.

Top Benefits of Machine Tooth

- Precision: Machine tooth ensures accurate cuts and shapes

- Efficiency: Reduces material waste and operational time

- Durability: High-quality materials extend the lifespan of machine tooth

- Versatility: Suitable for a wide range of applications and materials

Maintenance and Care for Machine Tooth

Proper maintenance is crucial for maximizing the lifespan and performance of machine tooth. Regular inspections, cleaning, and lubrication can prevent wear and tear, ensuring that tools remain in optimal condition.

Best Practices for Machine Tooth Maintenance

- Regularly inspect for signs of wear or damage

- Clean tools after each use to remove debris

- Apply appropriate lubricants to reduce friction

- Store tools in a dry, secure location

Materials Used in Machine Tooth Production

The choice of materials for machine tooth production significantly impacts its performance and durability. Common materials include high-speed steel, carbide, and ceramic, each offering unique properties suited for specific applications.

Popular Materials for Machine Tooth

- High-Speed Steel: Known for its hardness and heat resistance

- Carbide: Offers exceptional durability and wear resistance

- Ceramic: Provides high-temperature stability and resistance to deformation

Innovations in Machine Tooth Technology

Recent advancements in machine tooth technology have focused on improving performance, reducing environmental impact, and enhancing user experience. Innovations such as advanced coatings, smart tools, and sustainable materials are reshaping the industry.

Emerging Innovations in Machine Tooth

- Advanced Coatings: Increase wear resistance and extend tool life

- Smart Tools: Equipped with sensors for real-time monitoring and data collection

- Sustainable Materials: Focus on reducing environmental impact

Challenges in Machine Tooth Usage

While machine tooth technology offers numerous benefits, it also presents certain challenges. Issues such as tool wear, material compatibility, and environmental concerns require careful consideration and management.

Common Challenges and Solutions

- Tool Wear: Implement regular maintenance and use high-quality materials

- Material Compatibility: Choose appropriate materials for specific applications

- Environmental Impact: Opt for sustainable materials and practices

Future Trends in Machine Tooth

The future of machine tooth technology looks promising, with ongoing research and development aimed at addressing current challenges and expanding capabilities. Trends such as automation, artificial intelligence, and green technologies are set to revolutionize the industry.

Upcoming Trends in Machine Tooth

- Automation: Increased use of robotics in machine tooth operations

- Artificial Intelligence: Integration of AI for predictive maintenance and optimization

- Green Technologies: Focus on sustainable and eco-friendly solutions

Conclusion

In conclusion, machine tooth technology plays a pivotal role in modern manufacturing and industrial processes. Its evolution has brought about significant advancements in precision, efficiency, and sustainability. By understanding the different types, applications, and maintenance requirements of machine tooth, businesses can optimize their operations and achieve better results.

We invite you to share your thoughts and experiences with machine tooth technology in the comments section below. Additionally, feel free to explore other articles on our site for more insights into the world of industrial technology. Together, let's continue to innovate and improve the future of manufacturing!

Data Sources: Materials Today, Engineering.com, ScienceDirect.